Excavator vehicle axle systems adopt different structural designs due to different application conditions. Locomotives and buses have axle boxes. The bearings are connected to the bogie through the axle box, and the bearings are connected to the bogie side frame through the load-bearing saddle. The bearings bear the impact loads generated between the wheelset and bogie frame, and also bear the axial loads generated when the vehicle turns.

The wheel bearing structure includes cylindrical roller bearings, cylindrical roller bearing units, tapered roller bearings, and tapered roller bearing units. According to the application requirements of the bearing, the wheel shaft bearing should have a long maintenance-free cycle, a structural design that facilitates maintenance, and high reliability. Wheel bearing classification and application Vehicle wheel bearings are divided into the following types according to the design technology and application of their models: cylindrical roller bearings, unit double row tapered roller bearings, unit single row tapered roller bearings, single row cylindrical roller bearings, Cylindrical roller bearings, unit cylindrical roller bearings. The unit is mainly used in axle boxes of railway locomotives, passenger cars, and urban rail vehicles. It is generally a double-row cylindrical roller bearing with sealing devices on both sides or two paired single-row cylindrical roller bearings with sealing devices on one side. The bearing unit is supplied The grease has been filled before installation, so there is no need to add grease during installation.

Because the bearing has an integral sealing device, it has a longer maintenance cycle. This type of bearing has a special internal structural design. The modified linear contact between the rollers and raceways avoids edge stress, making the bearing particularly suitable for bearing high radial loads in applications, and can also bear part of the axial load. Compared with tapered roller bearing units, cylindrical roller bearing units are easy to disassemble and assemble, making it convenient for bearing inspection and maintenance.

Double row cylindrical roller bearings, unit matched single row cylindrical roller bearings, unit double row tapered roller bearings, the unit bearing unit has a complete seal, and the grease has been filled and the clearance has been adjusted before delivery and installation. , the overall unit design facilitates the installation and disassembly of the bearing, and the bearing is mounted on the journal through cold pressing installation method.

Pulp and paper bearings Meeting the needs of a challenging industry Market forces and increasingly stringent regulatory requirements make it more difficult than ever for pulp, paper and paper converting operations to be profitable. Competition is fierce a

More

In the past, many car wheel bearings used single-row tapered roller or ball bearings in pairs. With the development of technology, car wheel hub units have been widely used in cars. The scope and usage of wheel hub bearing units are growing day by day, an

More

Making each farm unique according to the growing needs/size of modern agriculture, location, elevation, climate, soil structure and crop rotation. Farm equipment needs to operate in many similarly challenging conditions, filled with mud, dust and debris;

More

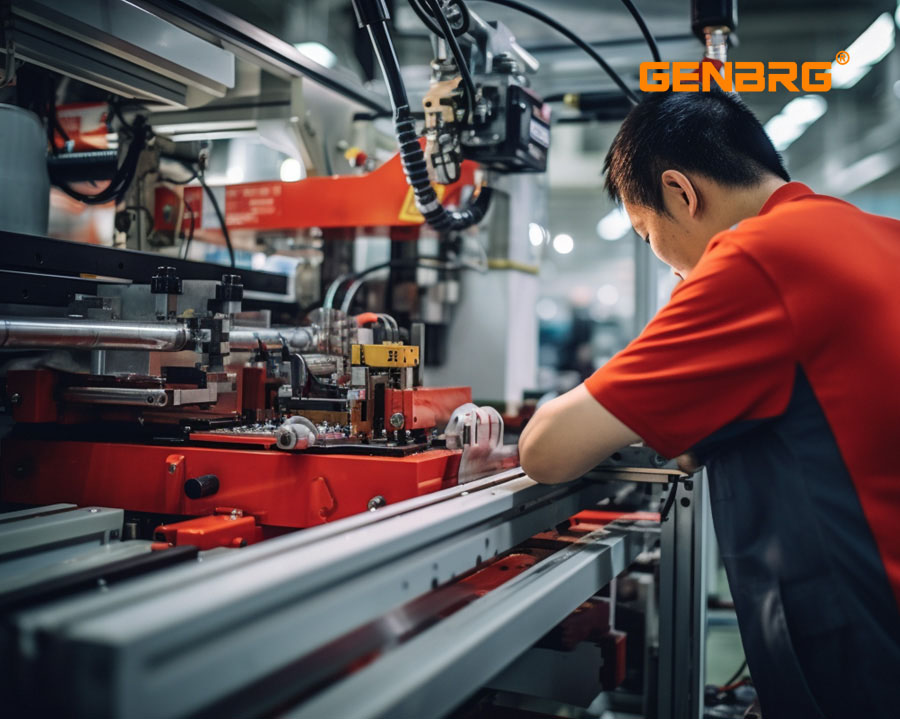

An automated assembly line is generally an organic whole composed of conveying equipment and professional equipment. It is a highly automated assembly production line based on electromechanical, information, imaging, and network integration. In the manufa

More